- Home

- Robot Simulation Software

Robot Simulation Software

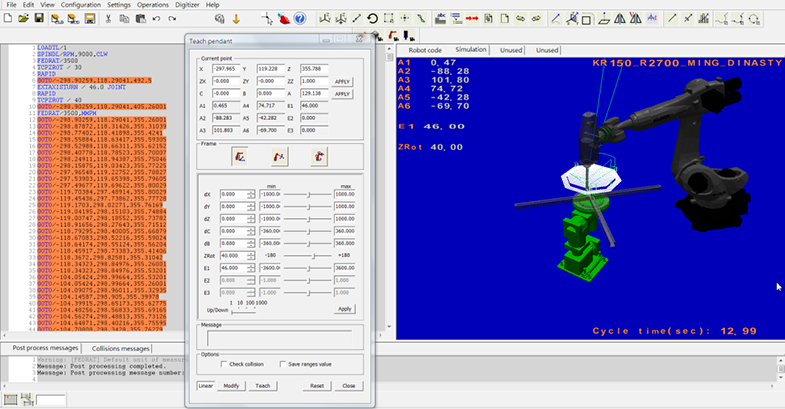

Robot simulation software application can convert machining code (G code or APT or ISO) generated by CAM into robot programming language.

Major Functions of Simulation Software:

Realistic Simulation

Realistic 3D dynamic scenes, including: Robots, Electric spindles, Tools, Workpieces and Final devices or any important components in the working area.

- Work Space Display And Inspection

- Working Hours Display.

- Operating Robot Work Area

- Collision Inspection

Freedom to Adjust Robot Through Multiple Axis

Users are allowed to let robot choose suitable moving angles manually or automatically during the cutters trails been executed.

- Single / Multiple Command TCP Z-axis Rotation Adjustments (TCPZROT).

- Independent Adjustments to Each Axis.

- Adjustments to Ground and Surface Coordinates (X, Y, and Z).

Management of The Robot's External Axes

It can be used to manage multiple external axes of robots, moving walking axes, rotating disks, and fixed work tables at the same time.

When the program is running, the positioning mode between the robot and the external axis and the working range of the robot can be coordinated and used.

When the program is running, the positioning mode between the robot and the external axis and the working range of the robot can be coordinated and used.

Offline Programming of The Robot

Managing tools through informations from user records, different ways can be adapted to show path trails and display imitative speed at position of feed rates and sites that reachable for robot. It can easily designed by off-line program.

RoboMove can also use coordinate input to carry out offline programming.

RoboMove can also use coordinate input to carry out offline programming.