- Home

- Tool Machine of CNC Robot Loading and Unloading Application

Tool Machine of CNC Robot Loading and Unloading Application

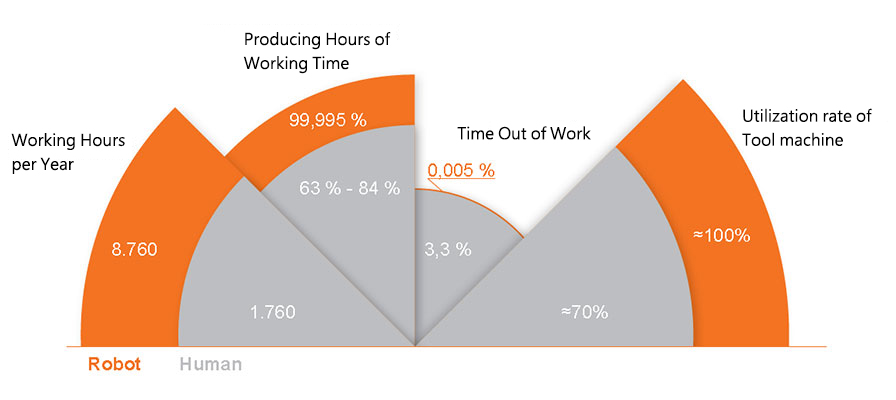

Higher economic benefit of robot with shorter period and robot higher producing efficiency. Outstanding and stabilized producing give robot extremely high economic benefit. Human indeed work faster and accurately than machine, but it only happened in first twenty minutes, after that human attention drop down. At the same time, a robot could continue working 24 hours per day, with same excellent quality. Without using robot, using rate of machine is about 70 %, otherwise the robot can offer 100% working hours no rest.

In response to the requirements of CNC digital machine tool automation, the use of 6-axis multi-joint loading and unloading robots can meet the requirements of "fast/large batch processing cycle", "saving labor costs", "improving production efficiency", etc., and meet the requirements of elastic clamping to the greatest extent. It can realize the automatic loading and unloading of workpieces such as discs, long shafts, gearbox bodies, irregular shapes, metal plates and other workpieces.

- Achieving flexible combining of multiple numerical control machines, multiple degree of automatic loading and unloading also workpiece clamping to satisfy hard demand of production technology.

- Industrial OCD visual detection is available to achieve free grabbing complete workpiece.

- Achieving single workpiece huge amount sustained production or multiple variety little amount automatic changing program production.

- High adjustability, achieving communication with other devices like CNC machine tool, PLC ,outer sensor ,controlled by safety reliable sequence through program design.

- Multi-functional : High performance preventing collision, product detection, external axis, stacking exc. optional function.

- It can easily realize multi-line automated production lines and "digital" factory layout, which saves manpower to the greatest extent and enhances the technical image of factory production.